By Eric Dusenbery, For the AJC

Troy Warren for CNT #Foodie

Finding success growing one of Georgia’s favorite products can be a hard nut to crack

Sitting in line at Morehouse Pecans in Irwinville, I am amazed by the activity.

The pickup truck in front of me has five or six bags of pecans. A small army of men descends to help with his tailgate and starts unloading. It reminds me of the scene from “Back to the Future” when Marty McFly travels back in time to downtown Hill Valley and notices the full-service Texaco gas station. Four attendants rush out to wash the windshield, check air in the tires and fill up the tank.

The pecan men open the bags to determine the variety of nuts. Another man cracks open a couple of nuts from each bag to analyze the quality and offer the customer the current price per pound. I watch with interest. After all, it is my first time bringing pecans to sell that we had gathered from our small farm. I am no casual backyard pecan grower, I think — I have four 50-pound bags myself. I stand a little taller next to my own pickup.

Lee Morehead is the pecan inspector and owner. I explain that it is my first time bringing in pecans since moving to South Georgia a year ago. We exchange small talk, then get down to business.

“This area you drove up to is for our backyard growers,” Morehead says.

“Uh, OK,” I think in my quick trip back to reality — I’m no big pecan grower, after all.

“We cater to commercial growers but have this spot here, too, for people like you,” Morehead explains as he points to an area where big trucks unload pecans — lots of pecans. “We get anywhere from a thousand pounds off of the commercial pecan trailer up to 10,000 pounds.”

Morehead inspects my pecans and makes me an offer. The pecan men take my pecans, weigh them and give me a ticket to collect my money. Then, they pour my pecans into large bins filled with the same kind of pecans as mine.

Inside the warehouse, huge bags filled with pecans are everywhere. A forklift driver takes away a full pecan bin and replaces it with an empty one.

In another room, a machine cracks the pecan shells — the first step in extracting the nuts. This is done for the backyard pecan growers who want to keep some of their own pecans. The cracker does not finish the entire job. It cracks and loosens the shells, but the nuts still have to be extracted by hand. This step does alleviate a lot of work and makes the end job easier.

‘A good fit for me’

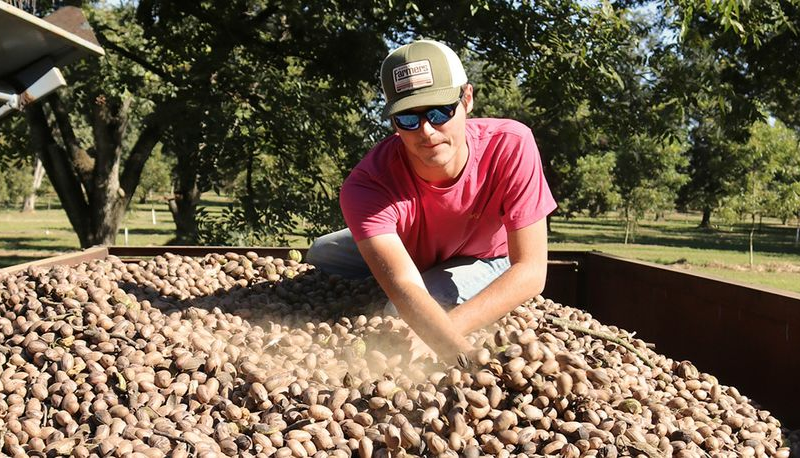

To get a sense of commercial pecan growing that puts my efforts in perspective, I go to Montezuma, Georgia, about 70 miles northwest of Irwinville, and meet with Cason Anderson of CCA Pecans.

Anderson is an unassuming 27-year-old and a first-generation farmer, which makes him unique in this industry. He grew up on 50 acres of land, but it was not a family farm. He found himself mowing with a Bush Hog and he was drawn to the outdoors while growing up and envisioned a life in farming, but wasn’t exactly sure how or with what commodity. While a senior in high school, he met a pecan grower who took him under his wing and provided Anderson with the background knowledge about pecan growing.

“Pecan farming seemed like a good fit for me,” Anderson says. “Pecan growing was easier to get into and didn’t require as much equipment or money as row crops.”

Anderson researched everything he could find about pecan growing and utilized the University of Georgia Extension Office publications and videos for step-by-step instructions.

He began making inquiries about land and equipment — two of the biggest challenges when starting an agricultural business. And he made an important decision — to come in through the back door. He didn’t buy the most expensive new trucks, tractors or equipment but sought used machinery that would still get the job done.

He also started contacting homeowners in the area who had a house with 5 to 10 acres of pecan trees and asked whether they would be interested in leasing their small orchards.

“These orchards were too small for the big growers to pursue, so I went after them myself,” Anderson says. A 10-acre lot here and a 20-acre lot there, and the total started adding up.

He now has 840 acres with the average orchard covering about 20 acres. (His own orchard is 60 acres.) That’s a lot of smaller farms to manage.

The art of shaking

Anderson gives me my first real introduction to commercial pecan growing when he drives up on a shaker. I hear it before I see it. And I watch as the yellow machine zigzags between rows of pecan trees. It looks like some weird cross between a zero-turn lawnmower and a tank.

Anderson maneuvers between the rows while guiding the shaker head to grab a tree. He uses a joystick in the cab to operate the hydraulics of a giant claw-looking device that clamps onto a tree and locks it in place.

And, then, the fun begins. The machine literally shakes the pecans off the tree. The tree shudders for about four to five seconds. Quickly, the ground is littered with fresh pecans, leaves and twigs. As fast as Anderson grabs the tree, he lets it go, backs up and locates the next victim. He speeds away.

The shaker is a marvelously designed machine. There are small sweepers by each tire that move the pecans away lest the tires run over and destroy the nuts. Anderson is protected from the falling pecans and debris by an enclosed cab, and the hydraulic shaker head can be maneuvered into any position to grab the tree. The clamp uses two rubber pads to protect the trees.

During the harvest season, Anderson completes two shakes at each orchard. The first shake will drop up to 80% of the pecans. A second shake will be completed, usually after Thanksgiving, in a kind of cleanup operation.

As Anderson speeds away, I’m left alone in the middle of the orchard. Morning sunlight filters through the tall pecan trees, and neat rows create a cathedral appearance. It’s peaceful as the thundering noise from the shaker dissipates.

Watching for problems

Last year, Anderson collected 750,000 pounds of pecans in a very good year. But the pecan harvest is not so plentiful every season. Several factors affect the harvest production, including climate.

According to Lenny Wells, University of Georgia Extension specialist in pecans, the rain and clouds of Georgia can generate specific problems for pecans.

“Pecan scab is the primary disease pecan growers battle,” Wells says. “Many of our commercial varieties, like Desirable and Stuart, can be highly susceptible to the disease. It is a fungal disease caused from frequent rainfall or just high humidity. The disease can turn the nuts completely black and cause them to drop from the tree unless managed with fungicide sprays.

“The other big issue is cloud cover. Pecans, like most plants, in addition to water, need plenty of sunlight. If we don’t get adequate sunlight during the growing season, the nuts don’t develop properly and we can run into some problems there. Because of the lack of adequate sunlight this year, particularly during September when the kernels were filling inside the nuts, we are seeing some of these issues.”

Historically, Georgia is the top pecan-producing state in the U.S., with a 142 million-pound crop; nearly twice that of New Mexico, the next closest state.

“We had a couple of down years after Hurricane Michael but reclaimed the crown again last year,” Wells says. “Hurricane Michael was by far the most damaging hurricane to the pecan industry in Georgia and resulted in over $500 million worth of damage to the industry. It was a huge, powerful storm centered on the heart of Georgia’s pecan industry and ended up affecting almost all pecan-growing regions in the state.”

Stages of production

The primary pecan-growing region of Georgia is centered along the Flint River from Mitchell County up through Albany and on to the Fort Valley area where Anderson’s orchards are located. Pecans seem to prefer loamy, sandy topsoil with a clay subsoil, and this is found throughout South Georgia.

The second step of the harvesting involves using a tractor to sweep the pecans away from the tree. Like a powerful broom, a sweeper attachment creates rows for collecting the pecans. The sweeper crawls along at a much slower pace than the shaker. A blower attachment also mounts to the tractor to blow some of the smaller leaves and debris away from the row of pecans.

Anderson has two of his three-person crew operating a sweeper/blower.

Next comes a V-sweeper harvester that collects the pecans.

“A 115-horsepower tractor pulls the harvester,” Anderson says. “The harvester is like a city street sweeper that removes trash from city streets. A large push broom merges the pecans into a row as they are gathered and moved along a series of rollers — a sort of conveyor system. A blower sifts some of the leaves, dirt and trash.”

The remaining pecans are deposited in a cart at the back of the harvester.

The harvester is in position but is not running correctly on this day. It’s a problem that needs repair before the pecans can be gathered.

“There’s just so many moving parts to these machines,” Anderson mutters as he shakes his head.

He and Tyler Raymo, another 20-something-year-old worker in the three-person crew, try to find the problem. They carefully crawl under the harvester and use various wrenches and pry bars to access the rollers of the harvester. They spend energy and daylight trying to get it repaired, but to no avail — they have to get outside repair help before they can harvest the pecans. A smile is never far from Anderson’s bearded face, and he takes the development in stride.

I return the next morning, a beautiful mid-60-degree day, after a minor repair on the harvester. This time, I see the machine before I hear it because it’s kicking up a cloud of dirt in the middle of the orchard.

Raymo is running the harvester and his windshield is covered with dirt. A wiper blade provides just enough visibility to maneuver the harvester to collect the row of pecans made by the sweeper the day before. After making a few passes along the length of several rows, it is time to dump a cart full of pecans into a large wagon.

Raymo operates a hydraulic lift to dump the pecans from the harvester cart into the separate wagon that is pulled by a truck. When full, the wagon will hold 17,000-20,000 pounds of pecans. A full wagon is transported to an off-site cleaner in the area where leaves, debris, smaller nuts that didn’t fully ripen and damaged pecans are removed. Finally, the pecans are further inspected for cracks, discoloration and other damage.

After the cleaning process, buyers take samples of the pecans and make offers to the farmers according to size and grade.

It can take seven to 10 years for a pecan tree to start producing. But once producing, they can provide pecans for up to 100 years. From what Anderson has seen, he believes the best production years for a pecan tree are between 10 and 40 years.

Not just a holiday gig

Anderson plans to stay in the pecan industry for quite some time, and he has a vision for the future. He hopes to accumulate about 1,000 acres of pecan trees, which will make him one of the larger operations in Georgia.

After a couple of days watching Anderson and his crew work, I think about the holidays looming. My thoughts turn to pecan pie and other pecan delicacies.

For Anderson, he just wants to get through the season with no other major issues.

“Some people think that we only work at this during the holidays,” he says. “But during the summer, we can put in 12-hour days mowing, spraying, working on irrigation and other maintenance on the orchard.”

Anderson holds back a few bags of pecans for family and friends during the season. His favorite holiday treats are milk chocolate pecans. But he likes them just roasted and salted, too.

“I love what I do. And I think we do pretty good to all be under 30 years old.”

In Other NEWS